Case Study: Charging Stations

Avoid delays in final assembly

Project overview

Charging stations manufacturer can meet ambitious launch schedule thanks to highly flexible deployment of the EuroQ team.

Urgently needed individual parts of charging stations shipped from China had to be unpacked and inspected at the port in Hamburg. Following this, we reworked them at several locations with our specialist personnel and packed them for onward transport.

The customer’s challenge

The manufacturer of the charging stations had outsourced the production of the individual parts to a Chinese supplier. In order not to jeopardize the launch during final assembly at the factory, the individual parts were to be checked upon arrival at the port. A number of the individual parts, some of which weighed several tons, had already been stored at the logistics service provider (LDL).

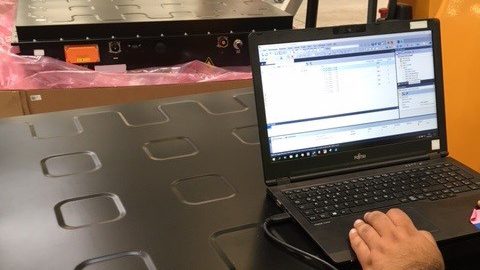

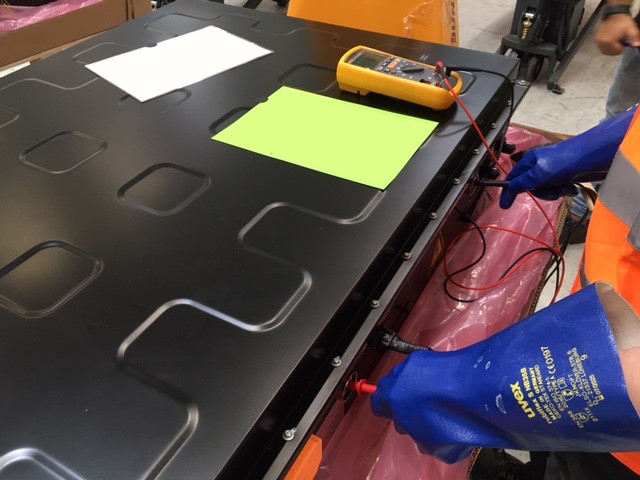

Staff with different qualifications were required to inspect and rework batteries / inverters / high-voltage circuit boards / coolant lines / surfaces and other components.

The demands on the quality service provider were high: skilled personnel with experience in the field of high-voltage, fault analysis/assessment and rework, a lot of flexibility and professional coordination between the Chinese supplier, the logistics service provider and the manufacturer of the charging stations.

Solution Story

-

Within a very short period of time, we assembled a team of experienced EuroQ high-voltage specialists for assessment, testing and rework.

-

This team was supplemented with additional specialists and flexibly deployed at the various locations. This allowed us to quickly resolve additional complaints that arose during the course of the project.

-

Our project manager took over the intensive process coordination on site and the constant exchange with the logistics service provider, the supplier (from China) and the manufacturer.

-

The customer received professional reporting, including itemization, to track defect patterns, sorting and rework, and to document the course of the project.

Do you need support?

Results

EuroQ – Performance

Your FPY is 75% – why isn’t anything changing?

ISO 9001 certification. Real added value or just a mandatory exercise?

Stephan Schneeweiss is driving EuroQ Eisenach forward

Locations

Our numerous locations in Germany and the USA are located in close proximity to the automotive manufacturers’ production plants.

Services

We help suppliers and OEMs achieve their quality goals – with our comprehensive expertise and broad portfolio.