Quality Inspector in Quality Control at EuroQ

As Quality Inspector at EuroQ, you work in quality control. In this job, you mainly check car components for defects and thus ensure that only flawless vehicles of optimal quality are produced at the manufacturer. This is an important task, because a car is only as good as its components. As vehicles and technologies become more and more complex, the demands on the quality of components and on our employees also increase.

Quality inspector, production assistant, quality tester, … is there a difference?

There isn’t. All of these terms refer to the same type of work. Since this is not an apprenticeship, but a job, companies use many different terms. At EuroQ, the job is called “quality inspector in quality control” and that is the primary task: you check a wide variety of automotive components to see if they are of good quality and are allowed to enter the production of car manufacturers.

The everyday work of a quality inspector

Which components do I work on?

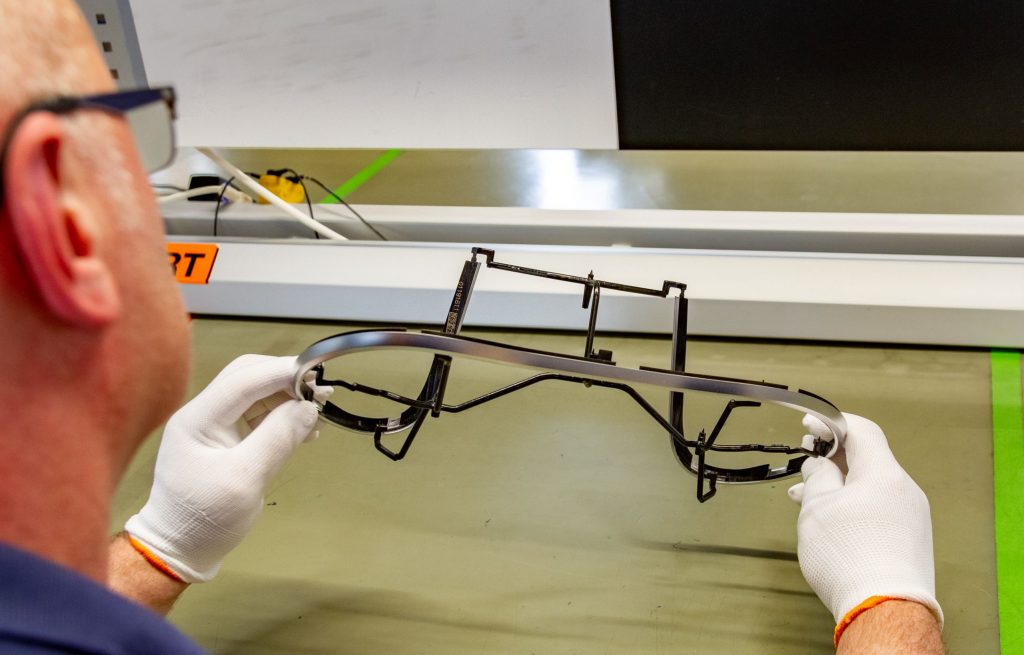

Depending on the project, you will work on a wide variety of components. Basically, everything that could be in your car is in the range of possibilities. We often must deal with a wide variety of interior trim, but add-on parts such as exterior mirrors or bumpers are also an option, as are cable harnesses, seals, engine components or windows. In fact, there is almost no component that we have not yet seen.

The same applies to materials: plastics, metals, glass, composites, or natural materials such as leather – everything is on the list.

How do I know what to check?

For the inspection, you will receive a briefing from your foreman for each job and a so-called “inspection instruction”. We don’t leave you on your own, but give you all the information you need to distinguish between intact and damaged components. And if you are unsure, your foreman will always be at your side to answer your questions.

Why are some of the components damaged?

There can be many reasons for this. Sometimes a machine was not operated correctly during production, or the manufacturer’s employees made assembly errors, for example. Often, we also must deal with damage that occurred during transport or due to faulty packaging.

What happens to damaged components?

You mark damaged components as NOK (non-OK) with a pen or sticker. What happens then varies from customer to customer. Some parts are scrapped, others are returned to the manufacturer or are repaired by us as part of a rework campaign.

Do I work with tools?

Your most important tools are your eyes and hands. However, we often use different measuring tools (we show you how to use them) and in some jobs even large machines (e.g., for magnetic particle inspection), for which you receive special additional training. For rework, we often use manual tools like screwdrivers and pliers, but also small machines like cordless screwdrivers.

What is rework?

When we are asked to not only inspect parts, but also repair them, we refer to this as an “inspection and rework project.” If the damage to the part allows it and our customer wants us to, we can rework faulty parts and make sure they can be installed after all.

Where do I work?

Most of the time you work in the hall at your EuroQ branch. Sometimes, however, we also have customer orders that are carried out in the vicinity of your branch. This can be directly in the production of the customer, but also e.g., in a logistics hall.

If you are willing and able, we also offer you the opportunity to help out temporarily at other locations as part of assembly assignments. In return, you will not only get to see interesting new places, but also get very good travel conditions with good hotels and at least 28€ net extra per day of work.

Do I work as a quality inspector in a team?

Yes. Depending on the assignment, teams can vary in size. Usually at least 3 – 5 quality inspectors and a foreman work together. In some cases, however, there can be significantly more colleagues.

Do I have opportunities for a promotion?

Absolutely yes! Many of our managers came to us as career changers themselves and have successfully developed their skills. Today, former production assistants / quality inspectors work for us as team spokespersons, foremen or even plant managers.

Requirements and qualifications for applying as a quality inspector

- In any case, you should have good eyesight (glasses are no problem) and be able to work standing up occasionally.

- Orderliness, reliability and diligence are also important qualities.

- Good German language skills are useful to be able to communicate with your colleagues and to read instructions.

- If you have completed a craftsman training, this can often be helpful. Especially when parts must be reworked.

- However, we are also happy to receive your application if you have a completely different education or no education at all.

- If you are motivated and don’t have “two left hands”, we will gladly teach you everything you need to know and be able to do.

- Since we sometimes have to enter data with a computer, it would be good if you have basic computer skills.

More information about the job as a quality inspector at EuroQ:

On our website euroq.eu you will find information about control and rework, about our locations and also about the company EuroQ.